Leakage(in CO2 storage) The escape of injected fluid from the storage formation to the atmosphere or water column of CO2Carbon dioxide into groundwater aquifers (no matter if this is through geological or man-made pathways) may degrade valuable groundwater resources, including drinking water reserves, may pose a riskConcept that denotes the product of the probability of a hazard and the subsequent consequence of the associated event to human health if hazardous trace metals dissolve into groundwater, and may interfere with agricultural activities. Although there is a significant experience from groundwater remediation of contaminants, CO2Carbon dioxide poses many unique challenges. In principle, three main remediation techniques can be applied (Esposito and Benson, 2012):

- Remediation using extraction wells. After the CO2Carbon dioxide leak into the aquiferAn underground layer of fluid-bearing permeable rock or unconsolidated materials (gravel, sand, or silt) with significant permeability to allow flow is stopped, a vertical or horizontal wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids is drilled that penetrates the CO2 plumeDispersing volume of CO2-rich phase contained in target formation. After the wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids is drilled, the extraction of fluid begins immediately. The wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids operates until the amount of CO2Carbon dioxide remaining in the reservoirA subsurface body of rock with sufficient porosity and permeability to store and transmit fluids is small or meets specific remediation specifications.

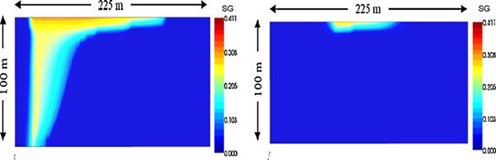

- Remediation using water injectionThe process of using pressure to force fluids down wells wells. The second remediation technique is to inject water into the aquiferAn underground layer of fluid-bearing permeable rock or unconsolidated materials (gravel, sand, or silt) with significant permeability to allow flow with the goal of halting the movement of the separate CO2Carbon dioxide phase through capillary trapping(CO2) Containment or immobilisation of CO2, there are four main trapping mechanisms: structural or stratigraphic trapping; residual CO2 trapping (capillary trapping) by capillary forces; solubility trapping by dissolution of CO2 in resident formation fluids forming a non-buoyant fluid; and mineral trapping where CO2 is absorbed by solid minerals present in the storage volume and dissolution. If more water is injected, all the CO2Carbon dioxide can be dissolved eventually in the water (Fig. 5-1).

- Remediation using injectionThe process of using pressure to force fluids down wells and extraction wells. This technique represents a combination of the previous two methods. It may bring the best results if multiple extraction and injectionThe process of using pressure to force fluids down wells wells are combined in a suitable scenarioA plausible description of the future based on an internally consistent set of assumptions about key relationships and driving forces; note that scenarios are neither predictions nor forecasts.

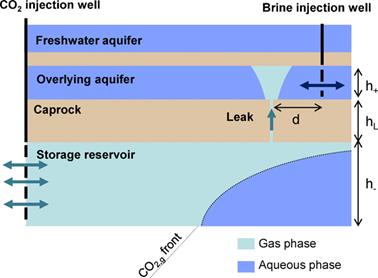

A special case of remediation measures, so called hydraulic barrier, can be used to stop a CO2Carbon dioxide leakage(in CO2 storage) The escape of injected fluid from the storage formation to the atmosphere or water column from the storage(CO2) A process for retaining captured CO2, so that it does not reach the atmosphere formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it into an overlying aquiferAn underground layer of fluid-bearing permeable rock or unconsolidated materials (gravel, sand, or silt) with significant permeability to allow flow. The underlying principle is to counter the driving forces of the migrationThe movement of fluids in reservoir rocks (natural CO2Carbon dioxide buoyancyTendency of a fluid or solid to rise through a fluid of higher density and injectionThe process of using pressure to force fluids down wells-induced overpressurePressure created in a reservoir that exceeds the pressure inherent at the reservoir depth) by increasing the pressure over the leak through brine or water injectionThe process of using pressure to force fluids down wells into the overlying aquiferAn underground layer of fluid-bearing permeable rock or unconsolidated materials (gravel, sand, or silt) with significant permeability to allow flow (Fig. 5-2). This technique is commonly used as a preventive or corrective measureMeasure taken to correct (remediate) significant irregularities or to prevent or stop leakages of CO2 from the storage volume in pollution engineering, e.g. in order to protect the drinking water against salt water intrusion in coastal areas. For CO2Carbon dioxide leakage(in CO2 storage) The escape of injected fluid from the storage formation to the atmosphere or water column remediation, however, the technique needs to be applied much deeper (Réveillère et al., 2012).

|

Fig. 5-1: The CO2Carbon dioxide gas saturation simulation results in vertical cross-section for a remediation scenarioA plausible description of the future based on an internally consistent set of assumptions about key relationships and driving forces; note that scenarios are neither predictions nor forecasts with one water injectionThe process of using pressure to force fluids down wells wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids (left-hand margin of the section, flow rate of 25 kg/s) after 2 days (left) and 33 days (right) depicting the reductionThe gain of one or more electrons by an atom, molecule, or ion in the gaseous phase plume size (Esposito and Benson, 2012). |

|

Fig. 5-2: Principle of CO2Carbon dioxide leakage(in CO2 storage) The escape of injected fluid from the storage formation to the atmosphere or water column remediation using the hydraulic barrier technique (Réveillère et al., 2012). |