A comprehensive monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions concept shall meet the different monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions purposes (see 1.1.1.) in the spatial dimension, and in the temporal dimension providing information on substances and processes of concern (see 1.3.4 and 1.3.5).

For practical purposes different compartments can be distinguished in the spatial dimension. These compartments fulfil different functions in storage(CO2) A process for retaining captured CO2, so that it does not reach the atmosphere operation and may comprise various subjects of protection. The individual compartments are accessible for installation and application of different monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions techniques. Relevant compartments to be considered for setting up a comprehensive monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions concept may include:

- storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it, including caprockRock of very low permeability that acts as an upper seal to prevent fluid flow out of a reservoir,

- secondary containmentRestriction of the movement of a fluid to a designated volume (e.g. reservoir) formations,

- the overburdenRocks and sediments above any particular stratum, including faults,

- injectionThe process of using pressure to force fluids down wells facilities, including wells,

- the hydraulic unitHydraulically connected pore spaceSpace between rock or sediment grains that can contain fluids where pressure communication can be measured by technical means and which is bordered by flow barriers, such as faults, salt domes, lithological boundaries, or by the wedging out or outcropping of the formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it., extending beyond the storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) complex,

- shallow, potable water aquifers,

- the marine environment,

- surface of the storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) site and surrounding biosphere.

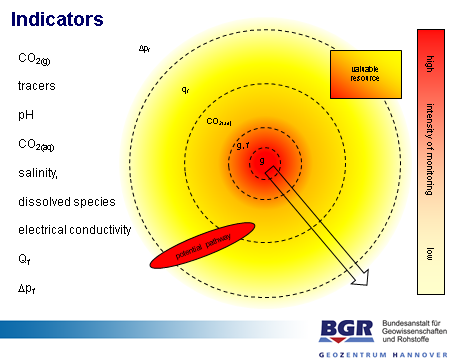

The practical delineation of a "storage(CO2) A process for retaining captured CO2, so that it does not reach the atmosphere complex" as defined in Art. 3 of the European CCSCarbon dioxide Capture and Storage Directive and the extent of it are a matter of ongoing debate. Depending on the position of the protagonists, it could be restricted to the first two compartments of the list above, or include the first five compartments. The term "surrounding environment" is not wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids defined by the EU CCS DirectiveDirective 2009/31/EC of the European Parliament and of the Council of 23 April 2009 on the geological storage of carbon dioxide either. However, it should include at least the area of the hydraulic unitHydraulically connected pore space where pressure communication can be measured by technical means and which is bordered by flow barriers, such as faults, salt domes, lithological boundaries, or by the wedging out or outcropping of the formation.. This list of compartments may be adapted to the local situations. For example, shallow potable groundwater resources and the marine environment may be mutually exclusive, or caprockRock of very low permeability that acts as an upper seal to prevent fluid flow out of a reservoir and reservoirA subsurface body of rock with sufficient porosity and permeability to store and transmit fluids may be split up into separate compartments. The different compartments are partially nested, adjacent or interconnected. Though the compartments are fixed in space, the phases within these compartments migrate with time within the compartments and may change at a particular site within a compartment. In general, there will be an outward migrationThe movement of fluids in reservoir rocks of different phases away from the injectionThe process of using pressure to force fluids down wells wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injection of fluids. In a saline aquiferAn underground layer of fluid-bearing permeable rock or unconsolidated materials (gravel, sand, or silt) with significant permeability to allow flow these expanding zones are (Fig. 1-3):

- supercritical(CO2Carbon dioxide) Conditions where carbon dioxide has some characteristics of a gas and some of a liquid CO2Carbon dioxide saturated reservoirA subsurface body of rock with sufficient porosityMeasure for the amount of pore spaceSpace between rock or sediment grains that can contain fluids in a rock and permeabilityAbility to flow or transmit fluids through a porous solid such as rock to store and transmit fluids near the injectionThe process of using pressure to force fluids down wells wells (g),

- partially saturated gas-water transition zone (g, f),

- CO2Carbon dioxide dissolved in formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it waterWater that occurs naturally within the pores of rock formations (CO2Carbon dioxide(aq)),

- zone of brine displacement (qf),

- outer zone of the hydraulic unitHydraulically connected pore spaceSpace between rock or sediment grains that can contain fluids where pressure communication can be measured by technical means and which is bordered by flow barriers, such as faults, salt domes, lithological boundaries, or by the wedging out or outcropping of the formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it., with negligible brine displacement but measurable pressure increase (Dpf).

|  Fig. 1-3: Schematic illustration of expanding monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions zones (dashed lines) and fixed features within different compartments (solid lines). Colours indicate monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity. An explanation of the labelling of zones is given in the text (Modified after may et al., 20112011 - Franz May, Gabriela von Görne, Falk WeinlichOutline of a regulatory framework for site exploration, safety concept, monitoring, and assessment of abandoned wellssee more). Fig. 1-3: Schematic illustration of expanding monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions zones (dashed lines) and fixed features within different compartments (solid lines). Colours indicate monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity. An explanation of the labelling of zones is given in the text (Modified after may et al., 20112011 - Franz May, Gabriela von Görne, Falk WeinlichOutline of a regulatory framework for site exploration, safety concept, monitoring, and assessment of abandoned wellssee more).

|

According to the various phases present in the zones, different monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions techniques are required to record key parameters or proxy data as indicators for subsurface processes. monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity will follow these zones and is generally more intensive in the dynamic region surrounding injectionThe process of using pressure to force fluids down wells wells and less intensive, at the margins of the hydraulic unitHydraulically connected pore space where pressure communication can be measured by technical means and which is bordered by flow barriers, such as faults, salt domes, lithological boundaries, or by the wedging out or outcropping of the formation.. However, areas of particular concern, such as potential pathways or valuable resources at the surface, may need special attention throughout all monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions phases. For monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions of fluid migrationThe movement of fluids in reservoir rocks processes and pathways the relations between compartments and zones have to be taken into account. Provisions for obtaining the required data have to be specified in the site-specific monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions plans.

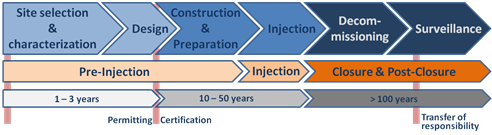

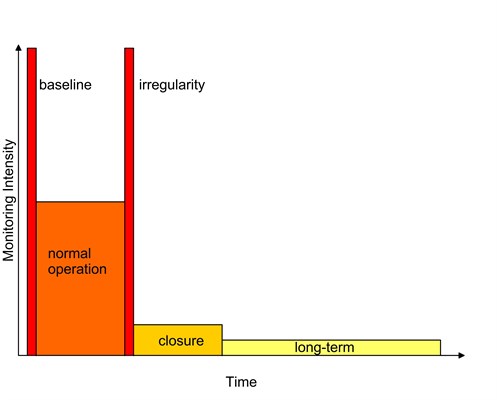

On the time scale different phases can be distinguished, which also will require different levels of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity (Figs. 1-4 and 1-5):

- Baseline monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions in the pre-injectionThe process of using pressure to force fluids down wells period,

- Standard operational monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions during normal injectionThe process of using pressure to force fluids down wells according to permit,

- Intensified contingency monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions during times of significant irregularities and following corrective measures,

- Closure and post closure period, before transfer of liability to the competent authority,

- Long-term monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions after the transfer of liability (Art. 18.6, EUEuropean Union CCSCarbon dioxide CaptureThe separation of carbon dioxide from other gases before it is emitted to the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) and Storage DirectiveDirective 2009/31/ECEuropean Commission of the European Parliament and of the Council of 23 April 2009 on the geological storage of carbon dioxide).

MonitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensities may be highest for baseline acquisition and during the injectionThe process of using pressure to force fluids down wells phase in case of irregularities and consecutive corrective measures (Fig. 1-5; Tab. 1-3). The general, descriptive term "intensity" includes the frequency of measurements, the numbers of sampling points and methods applied. Apart from these peak times, monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity may be reduced if injectionThe process of using pressure to force fluids down wells performance is according to plans. After the end of injectionThe process of using pressure to force fluids down wells and transfer of liability, the monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions efforts may be reduced to a level, which allows for detection of Leakages or significant irregularities. Slow geochemical processes, e.g. may lead to risks, long after site closure. If any leakages or significant irregularities are detected, monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions shall be intensified again.

|  Fig. 1-4: Phases of CO2Carbon dioxide geological storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) projects from a monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions perspective. Fig. 1-4: Phases of CO2Carbon dioxide geological storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) projects from a monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions perspective.

|

| Table 1-3. Level, scale and monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity considering the purpose and type of observations required. | Level | Scale | Intensity | Purpose | Observations | | normal operation, after transfer of responsibilityTransfer of all rights and obligations associated with a storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) site to a designated authority; will normally be granted when the obligations in the site closure permit has been met with an adequate level of confidence | regional | low | reconnaissance | indicative parameter, proxies | | significant irregularityAny irregularity in the injectionThe process of using pressure to force fluids down wells or storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) operation or in the condition of the storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) volume itself, which implies the riskConcept that denotes the product of the probability of a hazard and the subsequent consequence of the associated event of a leakage(in CO2Carbon dioxide storage) The escape of injected fluid from the storage formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it to the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) or water column or riskConcept that denotes the product of the probability of a hazard and the subsequent consequence of the associated event to the environment or human health | restricted area | moderate | search and detection | direct measurements | | leakage(in CO2Carbon dioxide storage) The escape of injected fluid from the storage formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it to the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) or water column, negative impacts | local | high | characterisation | flux and magnitude determination | |

|  Fig. 1-5: Schematic illustration of variable monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity with time (after v. Goerne et al., 20102010 - G. v. Goerne, F. Weinlich, F. MayAnforderungen und Vorschläge zur Erstellung von Leitfäden und Richtlinien für eine dauerhafte und sichere Speicherung von CO2 Stability-Abschlussberichtsee more). The occurrence of an irregularity has been placed arbitrarily towards the end of the operational phase. This does not imply that a site has to be closed after such an incident. Fig. 1-5: Schematic illustration of variable monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity with time (after v. Goerne et al., 20102010 - G. v. Goerne, F. Weinlich, F. MayAnforderungen und Vorschläge zur Erstellung von Leitfäden und Richtlinien für eine dauerhafte und sichere Speicherung von CO2 Stability-Abschlussberichtsee more). The occurrence of an irregularity has been placed arbitrarily towards the end of the operational phase. This does not imply that a site has to be closed after such an incident.

|

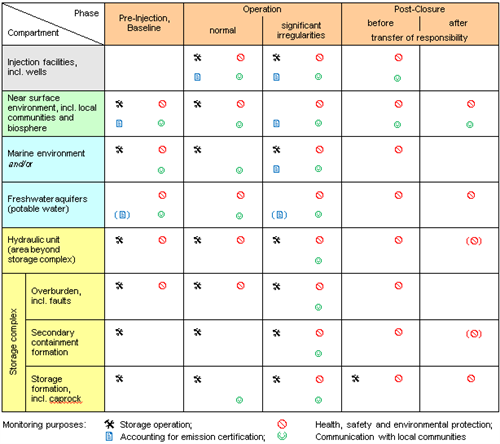

Temporal and spatial scales can be combined to a generic table. Allocating monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions purposes (see Section 1.1) on this table yields a matrix that can be used to generate comprehensive lists of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions tasks (Tab. 1-4). The arrangement of the compartments according to their occurrence with depth represents potential pathways for continuous transition from the actual storage(CO2Carbon dioxide) A process for retaining captured CO2Carbon dioxide, so that it does not reach the atmosphereThe layer of gases surrounding the earth; the gases are mainly nitrogen (78%) and oxygen (around 21%) formationA body of rock of considerable extent with distinctive characteristics that allow geologists to map, describe, and name it up to the surface, where injectionThe process of using pressure to force fluids down wells facilities are usually located.

For establishing site-specific monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions concepts local settings and features must be wellManmade hole drilled into the earth to produce liquids or gases, or to allow the injectionThe process of using pressure to force fluids down wells of fluids known and site-specific risks need to be addressed. Plans must be kept sufficiently flexible in order to react in cases of significant deviation from the predicted behaviour, either through more intensive monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions efforts or by monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions the effectiveness of corrective actions according to an associated safety concept.

May et al. (2011) proposed a Structured procedure for preparing site-specific monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions plans, including the following steps:

- Mapping of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions areas;

- Classification of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions intensity;

- Definition of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions tasks;

- Selection of monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions methods;

- Specification of measurements and observations.

Within this procedure, the allocation of the purposes to the matrix (Tab. 1-4) can be used to verify the completeness of site-specific monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions plans. Integrating various monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions purposes and tasks helps reducing the number of methods required to provide all the information needed for safe, durable and environmentally friendly storage(CO2) A process for retaining captured CO2, so that it does not reach the atmosphere of CO2Carbon dioxide during the entire life-time of a project. Examples for site-specific monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions plans are given in Chapter 4.

| Tab. 1-4: Comprehensive, generic monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions framework: monitoringMeasurement and surveillance activities necessary for ensuring safe and reliable operation of a CGS project (storage integrity), and for estimating emission reductions purposes with regard to different compartments and project phases (may et al., 20112011 - Franz May, Gabriela von Görne, Falk WeinlichOutline of a regulatory framework for site exploration, safety concept, monitoring, and assessment of abandoned wellssee more). Symbols in brackets indicate the need of case-specific considerations.

|